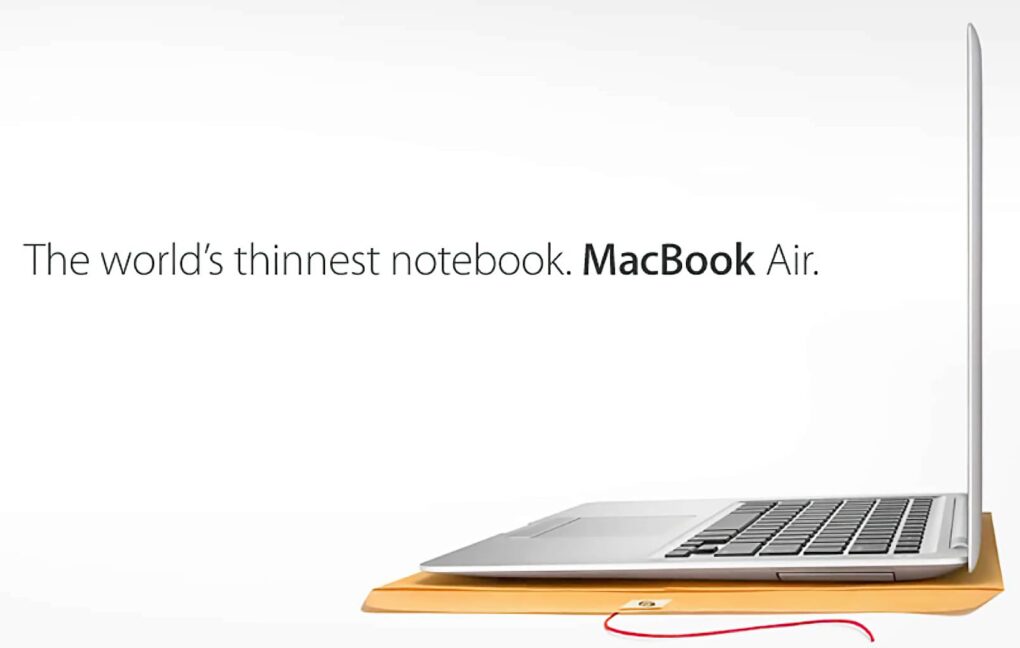

January 15, 2008: Apple CEO Steve Jobs shows off the first MacBook Air at the Macworld conference in San Francisco, calling the revolutionary computer the “world’s thinnest notebook.”

January 15, 2008: Apple CEO Steve Jobs shows off the first MacBook Air at the Macworld conference in San Francisco, calling the revolutionary computer the “world’s thinnest notebook.”

The 13.3-inch laptop measures only 0.76 inches at its thickest point and 0.16 inches at its tapered thinnest. It also boasts a unibody aluminum design, thanks to an Apple engineering breakthrough that allows the crafting of a complicated computer case from a single block of finely machined metal.

In a brilliant piece of showmanship during the MacBook Air launch, Jobs pulls the super-slim laptop out of a standard interoffice envelope. (You can watch his keynote introducing the MacBook Air below.)

October 20, 2009: Apple goes big with its iMac redesign, introducing the first 27-inch all-in-one Mac. The sleek, sophisticated aluminum unibody design looks so good that the iMac will remain virtually unchanged for years.

October 20, 2009: Apple goes big with its iMac redesign, introducing the first 27-inch all-in-one Mac. The sleek, sophisticated aluminum unibody design looks so good that the iMac will remain virtually unchanged for years.

![Apple pledges to spend another $100 billion on US manufacturing [Updated] Apple spends more on US manufacturing](https://www.cultofmac.com/wp-content/uploads/2025/08/Apple-invests-100-billion-more-in-US.jpeg)

![Apple and Foxconn, a history [Cook book outtakes] Foxconn workers spell company's name](https://www.cultofmac.com/wp-content/uploads/2019/04/Foxconn-banner.jpg)

![How Ops operates back at Apple HQ [Cook book outtakes] Apple leases new offices near to Apple Park](https://www.cultofmac.com/wp-content/uploads/2018/01/Apple-Park.jpg)

![Inside Apple’s factories [Cook book outtakes] Apple factory workers in China](https://www.cultofmac.com/wp-content/uploads/2019/04/Apple__factory_worker_China__banner.jpg)