No matter what the reason, or who was at fault, the collapse in Apple’s relationship with former sapphire supplier GT Advanced Technologies came down to one thing: the latter company wasn’t able to meet Apple’s terms.

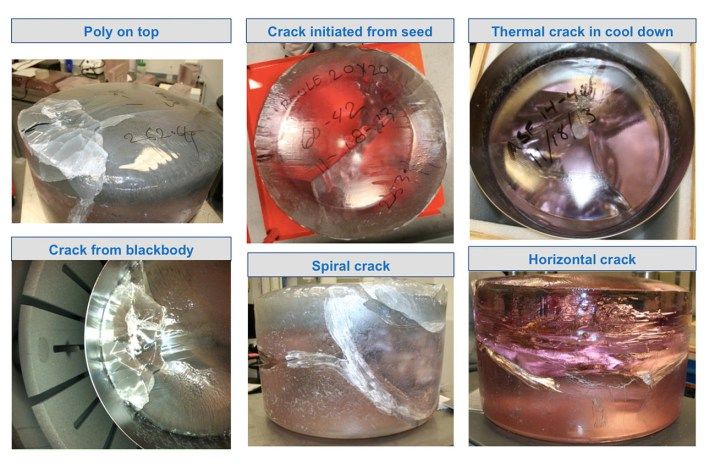

Now photos published by the Wall Street Journal show some of GTAT’s sapphire errors, made just days before Apple signed a deal for the company to produce sapphire displays to be used in next generation iPhones. The 578 pound sapphire cylinders — known as boules — featured multiple flaws, which rendered the majority unusable.

While Apple certainly pushes its manufacturers hard to seemingly achieve the impossible on tighter and tighter profit margins, the picture that emerges from the WSJ article is of GT as a chaotic company, struggling from the very start to fulfil Apple’s expectations.

Hiring was reportedly done so quickly that more than 100 new employees didn’t know who they reported to, a former manager claims. Another report says that there was no policy for attendance, resulting in a higher than usual number of “sick days.”

“We just kept sweeping the floors over and over,” one particularly telling quote says, noting that hiring was done before GTAT had even built enough furnaces to start work. “I just saw money flying out the door.”

Despite it taking 30 days and around $20,000 to produce a single boule of sapphire, more than half of these were totally unusable. At one point in August, GTAT reportedly discovered that 500 sapphire bricks (produced by laser-cutting the boules) were missing — only to find out later that they had been sent to recycling instead of shipping.

In all, the GT Advanced Technologies/Apple partnership seems to have been a disaster all-round, which is a shame not only because it cost a lot of people jobs and denies users sapphire displays for their iPhone, but also because this was a highly-publicized attempt to bring manufacturing back to the U.S., after years of China-based production.

Apple has recently been talking about trying to repurpose its Mesa, Arizona factory, although both of its new sapphire producers (for the Apple Watch) are reportedly based in Asia.

5 responses to “This is why the iPhone 6 didn’t get a sapphire screen”

This is why we can’t have nice things!

And GT have the gaul to blame Apple and threaten to sue??? Classy!

Murica!

I think the most telling thing from the WSJ article is that that GT accidentally sent a huge amount of processed and useable sapphire to be recycled. They literally could get the most basic part os their business working correctly. This is like a foundry chucking smelted gold in the bin. Insane.

They tuk ar jobs!!!