Apple pledged Wednesday to make 100% of the glass screens on all iPhones and Apple Watches in the United States for the first time. The company committed $2.5 billion as part of its expanding partnership with Corning, which will produce the iPhone and Apple Watch cover glass at its plant in Harrodsburg, Kentucky.

“We’ve worked with our partners at Corning to build the world’s largest and most advanced smartphone glass production line,” Apple CEO Tim Cook said during a White House briefing Wednesday afternoon, during which he committed an additional $100 billion investment in American manufacturing. “I’m pleased to announce that very soon — this is for the first time ever — every single new iPhone and every single new Apple Watch sold anywhere in the world will contain cover glass made in Kentucky.”

Apple to make 100% of iPhone and Apple Watch Screens in U.S.

The $2.5 billion boost for Corning is part of Apple’s $600 billion investment in U.S. manufacturing, spurred (or at least intensified) by the threat of tariffs imposed by President Donald Trump. Apple continues to finesse its massive worldwide supply chains to minimize the effects of constantly shifting tariffs.

The moves, which previously included shifting nearly all manufacturing of U.S.-bound iPhones from China to India, will bring at least a portion of Apple’s massive iPhone and Apple Watch manufacturing supply chains back to the United States. However, the idea of an entirely made-in-America iPhone remains the stuff of fantasies, at least in the near term.

“Corning is a storied American company, and we’re thrilled to work together to build the largest and most advanced production line ever created for smartphone glass,” said Cook in a statement Wednesday. “Thanks to the power of American manufacturing, any customer anywhere in the world who buys a new iPhone or Apple Watch will be holding precision glass made right here in Kentucky.”

Corning will build ‘world’s largest and most advanced smartphone glass production line’

Photo: Apple

Apple explained the importance of the $2.5 billion investment like this:

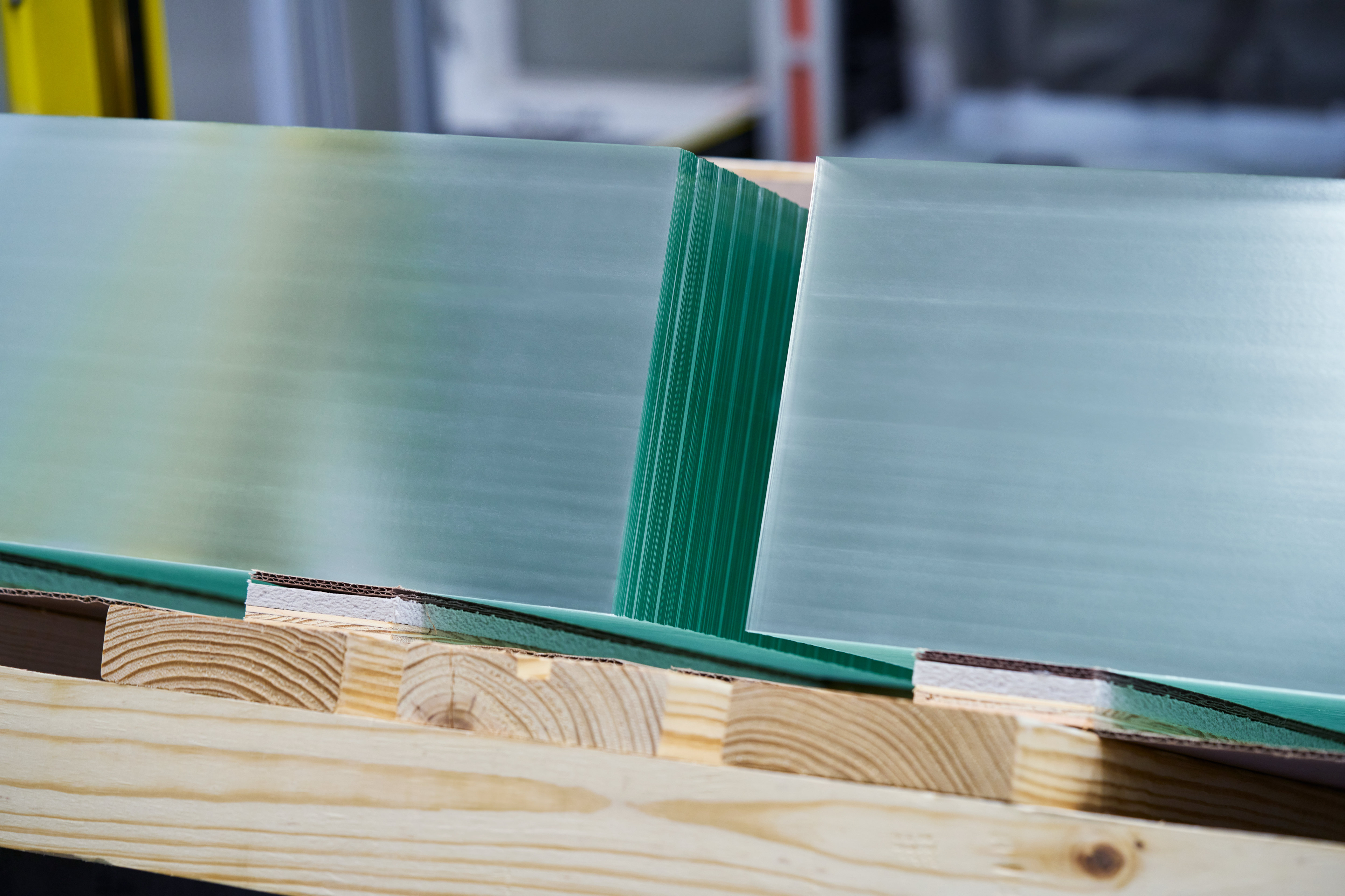

Corning is creating the world’s largest and most advanced smartphone glass production line at the Harrodsburg facility. Corning will now dedicate this entire facility to manufacturing for Apple, which will help increase Corning’s manufacturing and engineering workforce in Kentucky by 50 percent. The two companies will also open a new Apple-Corning Innovation Center at the Harrodsburg plant. The Innovation Center will play a key role in the development and engineering of advanced materials and next-generation manufacturing platforms for Apple’s future generations of products.

“Apple is an amazing partner for American manufacturers like us, and together, we’ve innovated and pushed the boundaries of what’s possible,” said Corning CEO Wendell Weeks in the same press release. “We developed and made the glass for the very first iPhone in Harrodsburg, Kentucky, 18 years ago. With this new multibillion-dollar commitment from Apple and the lighting of our most advanced manufacturing platform, we are hiring more people and bringing 100 percent of Apple’s cover glass needs for iPhone and Apple Watch to the original home of the innovation.”

Over the years, Apple invested almost $500 million in Corning’s Kentucky manufacturing operations, “with billions more spent on glass manufactured in the U.S.,” Apple said.

Corning makes the damage-resistant cover glass known as Ceramic Shield — which Apple calls “the toughest in any smartphone” — that is used in current iPhones.

Cult of Mac asked Apple what the previous percentage of iPhone/Apple Watch cover glass made in the United States was, as well as what companies produced it and where. We will update this article when Apple responds.

Apple’s American Manufacturing Program pushes U.S. manufacturing

Photo: Apple

Apple said the Corning deal is part of its “American Manufacturing Program (AMP), which will invest across America and incentivize global companies to onshore production and manufacture even more of Apple’s critical components in the United States.”

“We’re grateful to the President and his administration for their support for American manufacturing, and we’re excited for the innovation this investment will unlock,” Apple said in the press release.

Corning also provides raw materials used by GlobalWafers, another company that’s part of Apple’s American Manufacturing Program. GlobalWafers “will use silicon from Corning to manufacture advanced bare wafers in the U.S. for the first time,” Apple said. “In that way, Corning also plays a key role in Apple’s supply chain for producing advanced silicon chips in America.”