It would be easy to think that Apple’s sapphire iPhone dreams went down the pan when GT Advanced Technologies went bust, but Apple’s nothing if not persistent.

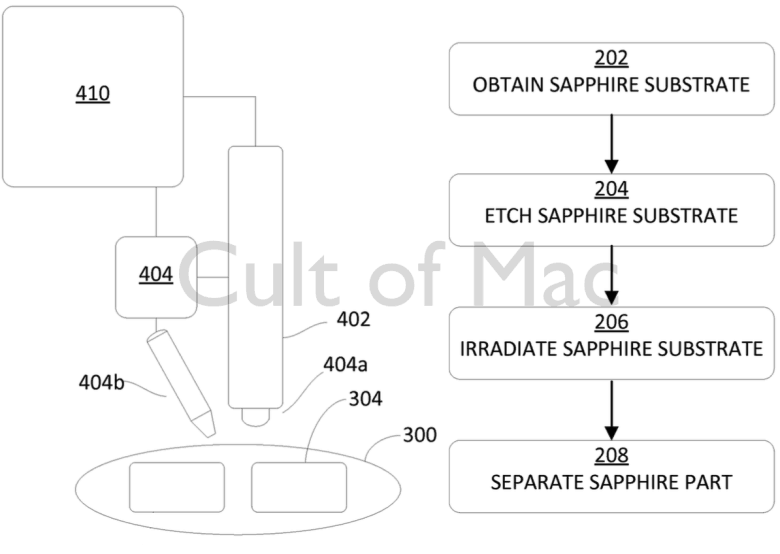

Today, the U.S. Patent and Trademark Office published a patent application from Apple describing a new method for manufacturing sapphire displays by irradiating the sapphire crystal and then using a laser and “second gas medium” to slice it into the super-thin sheets Apple requires.

Photo: USPTO/Apple

As Apple’s application explains, sapphire crystal is paradoxically both incredibly hard and very brittle. The sapphire itself rates 9.0 on the Mohs scale, which means that it is capable of scratching almost all other minerals — including physical cutting tools.

However, it is also delicate in the sense that small defects in the surface or edge of a sapphire substrate can result in “dramatic strength reductions.”

To solve this, Apple’s efficient laser-cutting patent application would save wear and tear on physical sapphire cutting tools, while also lowering the number of defects made. This in turn would have a positive impact on the all-important yield, necessary to churn out tens of millions of devices.

True, Apple could use this technology for focusing on smaller sapphire components like camera lens covers and Apple Watch displays, but the patent application specifically mentions “mobile phone” as a desired category. All of the diagrams (such as the one above) also show iPhone-size displays being cut.

Now Apple just needs to work out where it’ll get the massive sapphire quantities it needs for its devices.

Source: USPTO