Over the years, Apple took heavy criticism for employing an offshore supply chain rife with abuse. The company is still stained by the rash of worker suicides in 2010 at Foxconn, its main supplier.

But as Apple’s latest Supplier Responsibility report shows, the company continues to make remarkable strides to improve conditions for workers and the environment.

Tim Cook leads the charge

Apple seems to be really cleaning up its supply chain under Tim Cook.

Before Cook took over as CEO in 2011, the company seemed to pay little attention to the conditions in its overseas factories. Steve Jobs was at best indifferent. But Cook, a man with a background in manufacturing who spent the early part of his career working on shop floors, seems sincere in his goal to improve the conditions of workers. He made improving labor practices a high priority. And he seems to be delivering.

The company’s latest Supplier Responsibility Progress Report, published earlier this week, shows encouraging progress in exorcising the demons from the Apple supply chain.

Consider these key findings from the 2019 report.

Apple eradicates child labor

Apple almost completely stamped out child labor, finding only one underage worker in its supply chain in 2018. (A 15-year-old faked an ID to get a job.)

When Apple finds underage workers, it forces the supplier to send them home, pay for their education, continue to pay their wages, and offer them a job when they reach legal working age. In this case, “The individual was immediately transported home and enrolled in his or her choice of school while continuing to receive wages from the supplier,” the report said. Pretty good deal for the kid — and not a bad way to get through school!

Underage labor used to be a big problem in Apple’s supply chain. Just six years ago, Apple found hundreds of cases of underage workers. Apple really started to crack down on child labor in 2013, when it axed a supplier for 74 underage labor violations. That year, Apple found about 170 cases of child labor at 11 facilities.

Photo: Apple

Much less bonded labor, too

Apple also almost completely eliminated debt-bonded labor, which the report calls “a form of modern slavery.” Debt-bonded labor is when a worker is forced to take a job to repay a debt (such as a fee to be smuggled into a new country), or when a fee is paid to a factory or recruiter to secure a job. According to the report, in 2018 Apple found two cases of bonded labor affecting 287 employees.

This might seem like a lot. However, in years past, bonded labor loomed as a much bigger problem. Just six years ago, Apple found tens of thousands of cases: In 2012, Apple made suppliers pay back more than $6.4 million to affected workers — equivalent to the wages of about 22,000 entry-level Foxconn employees. Since 2008, Apple has forced suppliers to repay almost $31 million in recruitment fees to 36,137 employees.

For its efforts, Apple won the Thomson Reuters Foundation’s Stop Slavery Award in 2018. The award recognizes companies working to eliminate forced labor from their supply chains.

The majority of labor violations Apple found this time were related to relatively minor issues like working hours and paying of wages and benefits. Workers sometimes worked excessive overtime, or were underpaid or denied benefits. Overtime, however, is a tricky situation, because many workers claim they want to work as much as possible to maximize their pay.

Apple makes environmental gains

On the environmental front, Apple continues to make big progress, too. The company says all of its final assembly plants for iPhone, iPad, Mac, Apple Watch, AirPods and HomePod are now certified Zero Waste to Landfill, which is pretty cool. Apple targeted the final assembly plants because they tend to generate the most waste. Cupertino even developed a new recyclable film that protects components like screens, diverting hundreds of tons of waste away from landfills.

Apple also reduced greenhouse gas emissions in the supply chain by more than 466,000 annualized metric tons. That’s equivalent to taking 100,000 cars off the road for a year.

And 30 suppliers have made commitments to using 100 percent renewable energy for making Apple products. That’s up from just a handful a couple of years ago. This is a big deal. Apple already powers its offices and stores by 100 percent green energy worldwide. But the supply chain, which accounts for the majority of the company’s cartoon footprint, continues to lag.

Apple committed to converting its suppliers to about 4 gigawatts of renewable energy by 2020. That’s about one-third of the energy needed to make its products. The company hopes to transform the remainder of the supply chain within a decade.

Meeting Apple’s standards

Photo: Apple

Apple’s 66-page report, the 13th annual deep dive into the company’s supply chain to date, proves surprisingly interesting. It gives an idea of the scope of Apple’s efforts to improve working conditions.

Keeping an eye on the Apple supply chain is a big operation. In 2018, the company performed more than 1,000 supplier assessments in 45 countries, scrutinizing everything from mines to recycling plants. The process seems rigorous. Among other things, Apple interviews workers, scrutinizes records, monitors media, and works with local oversight groups worldwide.

The company then works for months trying to correct abuses. “Following an assessment, we partner with a supplier to develop a corrective action plan to make improvements where needed,” the report says. “Ongoing engagements with our suppliers can include months on the ground working with suppliers, providing training, tools, and support to help them meet our standards.”

Apple’s push for ethical manufacturing

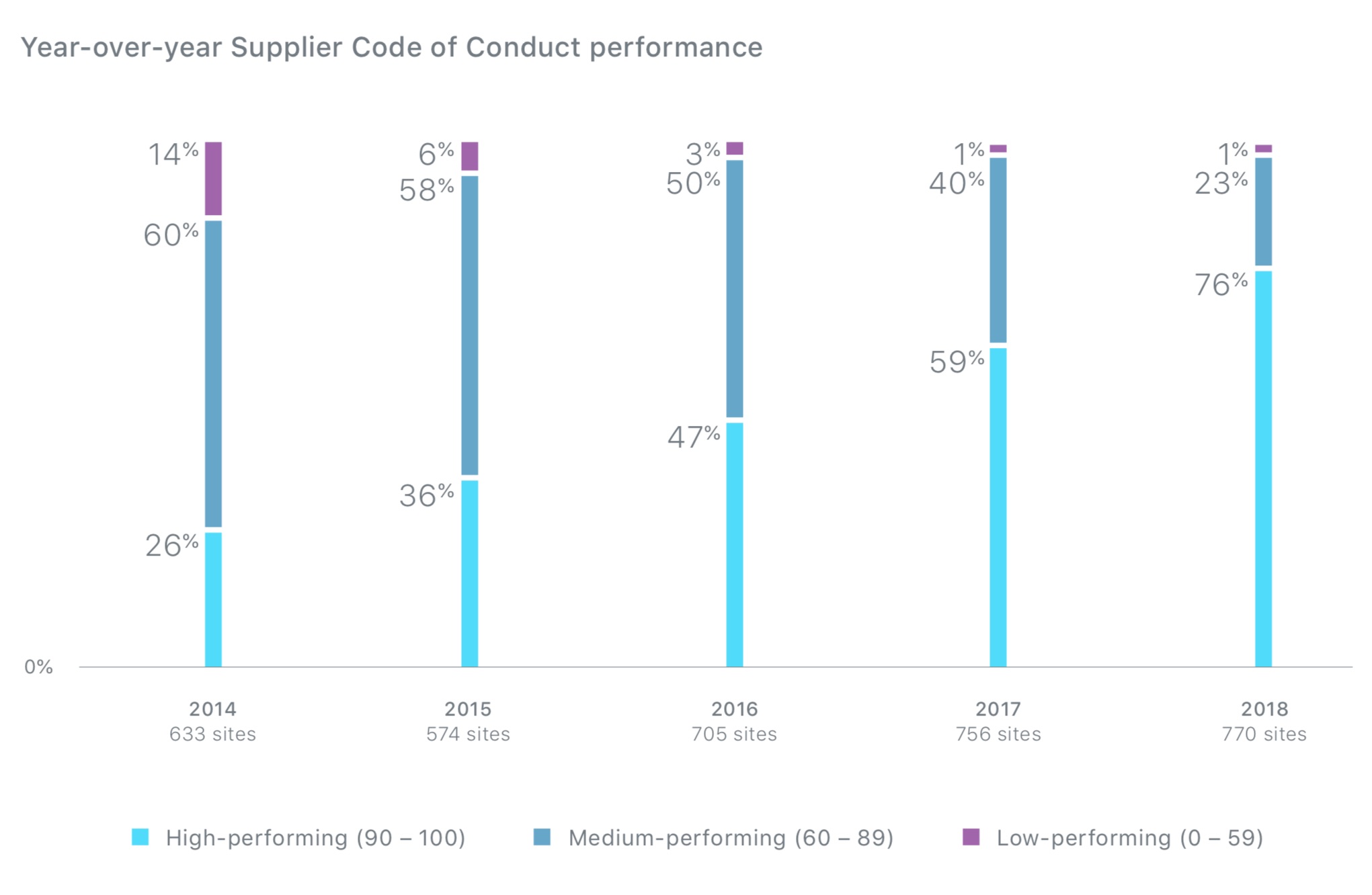

All that effort is clearly paying off. As can be see from the chart above, in just four years the majority of Apple’s suppliers have been brought into compliance (high-performing). Fewer than a quarter hit that mark just four years ago.

Of course, this is all self-reported, so we have to take Apple’s word for it. Apple does, however, work with dozens of third-party groups and organizations, so there is some oversight. And really big reforms — like allowing workers to unionize — seem a long way away.

Nonetheless, Apple’s offshore supply chain is a lot more friendly, to workers and to the environment, than it was just a few years ago. And it has a lot to do with Tim Cook.

Leander’s new book about Tim Cook, entitled Tim Cook: The Genius Who Took Apple to the Next Level, will be published on April 16. The book can be preordered from Amazon.

![Apple whips its gigantic global supply chain into shape [Opinion] Apple supply chain worker inspecting glass](https://www.cultofmac.com/wp-content/uploads/2019/03/Apple_Supplier_Responsibility_Report_2019_1.jpg)