Apple’s business model is based on the future, but sometimes a fan pines for the machine they had as a kid.

Apple’s business model is based on the future, but sometimes a fan pines for the machine they had as a kid.

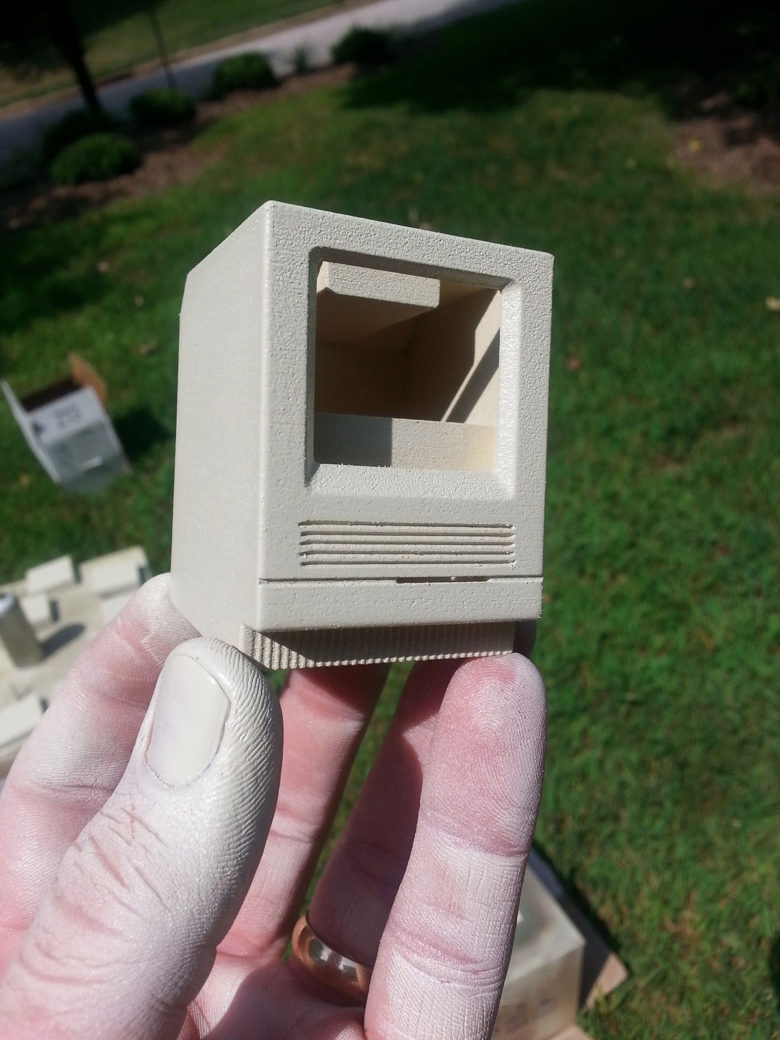

Self-taught hardware hacker and 3D printer artist Charles Mangin happily tries to satisfy those vintage tech longings by recreating pieces of Apple’s past in miniature. He even brings the screens to life — sort of.

Mangin, who makes tiny 3D-printed versions of machines like the Apple IIc or the 1984 Macintosh, is one success story from the fringes of Apple culture, where people fill a unique niche by creating something that engages the Apple user’s on an emotional level.

Cult of Mac has profiled people like Parry Gripp, whose parody songs about the iPhone were a springboard to a music career, Roberto Hoyos, who made pillows from OS X icons for a girlfriend and turned the idea into a successful throw pillow company and Jonathan Zufi, who taught himself photography to create a beautiful coffee table book on Apple’s history.

Photo: Charles Mangin

Likes to tinker

Mangin, who lives and works in Raleigh, NC, is not about to quit his day job as an Apple technology IT consultant. But the tech tinkerer who taught himself the various sculpting programs for 3D printing loves to engage his inner geek by collecting Apple computers and miniaturizing their likenesses into working toys and even a little jewelry making.

“There’s a creative aspect to it even though I am copying something that exists,” Mangin told Cult of Mac. “How am I going to take this thing that is a foot-and-a-half tall and shrink it? This engages the creative part of my brain.”

Mangin gets creative by making the diminutive Apples functional. His ’84 Mac was designed to hold an iPod Nano or Apple Watch, giving it a screen that lights up.

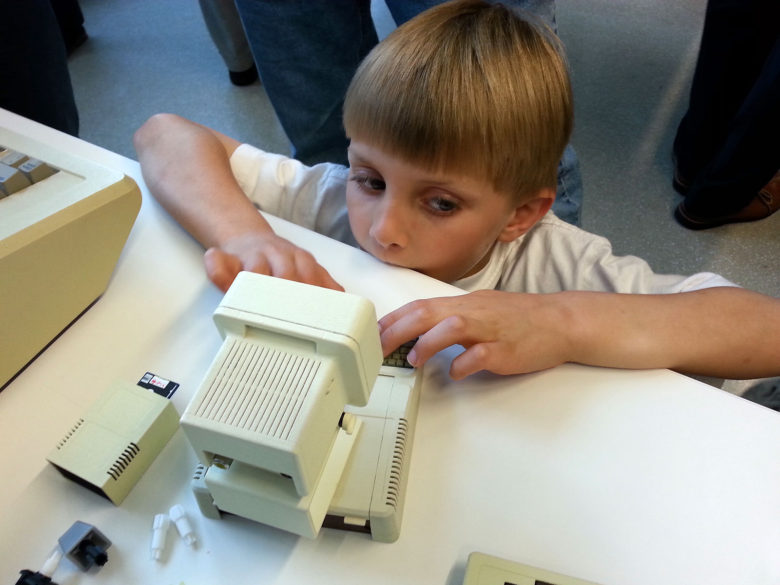

Photo: Charles Mangin

He recreated a disk drive to function as an SD card reader and he has made versions of the Apple II, III and Lisa to house a Raspberry Pi computer.

From start to finish

Mangin will peer inside old machines in his collection to see how pieces fit together, study photos and patent drawings, and then spend several hours in iDraw and the 3D-sculpting program Autodesk 123D to scale down the pieces with absolute attention to detail.

He then uploads the files to the 3D printing company Shapeways, which sends back the printed pieces within a week. Mangin then sands, paints and assembles the little Apple. It takes about three weeks, including some 20 hours of time on the computer, before he can ship a completed piece to a customer.

Photo: Charles Mangin

Photo: Charles Mangin

There are a couple of ways to obtain these little Apples. You can order one from his Esty site or, if you have a 3D printer at home, you can obtain the plans for free on thingsiverse.com.

He has produced about 160 pieces, having sold more than 100, and printed an old Atari setup and a tiny mouse for the 84 Mac replica on request.

Photo: Charles Mangin

3D printing has emerged from the expensive large-scale industrial prototyping to hobbyists, artists and start-up entrepreneurs who make everything from toys, replacement parts for machines and even prosthetic limbs.

“Hobbyists began making their own machines with inkjet parts,” Mangin says about the growth of consumer 3D printing. “It parallels what was happening with personal computers in garages. It’s the late 70s and 80s all over again.”

Here is a 15-minute time lapse of Mangin creating a replica Apple III.