No Apple fan is oblivious to the huge amount of science, technique, expertise and care that Apple puts into every product. Apple doesn’t design its products the way it does because it has to, but because it is compelled on a profoundly spiritual level to do so.

For the Apple Watch, Apple has taken that care to the next level. And if you want to see just how much artistry, skill, craft and passion has gone into creating the latest revolutionary Apple product, there’s no better way to spend the weekend than reading about the behind-the-scenes manufacturing process of the Apple Watch.

Over at the Atomic Delights blog, Greg Koenig of Luma Labs has gone through all the videos detailing the Apple Watch manufacturing process, and explained in layman’s terms what this all means.

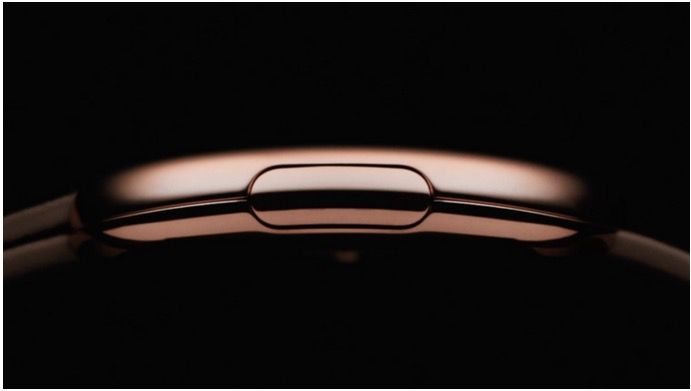

And what does it mean? Simply this: Apple has put a level of attention into creating the Apple Watch that it has never applied to any other product. This isn’t an iPhone for your wrist. Apple is constructing its smartwatch in such a way that it puts Rolex to shame.

Here’s the money quote:

Jony Ive often speaks of care. It is an odd word to use as it doesn’t imply the traditional notion of “craftsmanship” in the classic, handmade sense. Nor does it imply quality or precision in the way a Japanese car manufacturer or German machine tool maker would. “Care” implies a respect for the raw materials and end result, with little concern about what it takes to link those two ends of the production chain together, and we see that highlighted with the Watch. Apple could very easily have forgone forging to create stainless steel cases, just like everyone else. Hardening gold alloy with cold working could have been eliminated, putting them on par with the rest of the industry. Nobody will see or feel the inside pocket for the microphone on the Sport, yet it has been laser finished to perfection.

I see these videos and I see a process that could only have been created by a team looking to execute on a level far beyond what was necessary or what will be noticed. This isn’t a supply chain, it is a ritual Apple is performing to bring themselves up to the standards necessary to compete against companies with centuries of experience.

If you care at all about how Apple makes things (and you should, because the care Jony Ive brings to Apple’s products is one we should all be trying to emulate in our personal lives), you owe it to yourself to spend the weekend reading Koenig’s post. You may not “need” an Apple Watch, but you simply cannot deny the artistry that went into creating Cupertino’s smartwatch.

Source: Atomic Delights