Apple has “sought incentives” to set up a manufacturing facility in India, according to a new report.

Apple reportedly made its case to the country’s Department of Revenue and Department of Electronics and Information Technology (DeITY).

Apple has “sought incentives” to set up a manufacturing facility in India, according to a new report.

Apple reportedly made its case to the country’s Department of Revenue and Department of Electronics and Information Technology (DeITY).

Apple’s new jet black iPhone 7 is nearly impossible to find at stores, and the shortage isn’t going to get better anytime soon, according to one of the most accurate Apple analysts in the game.

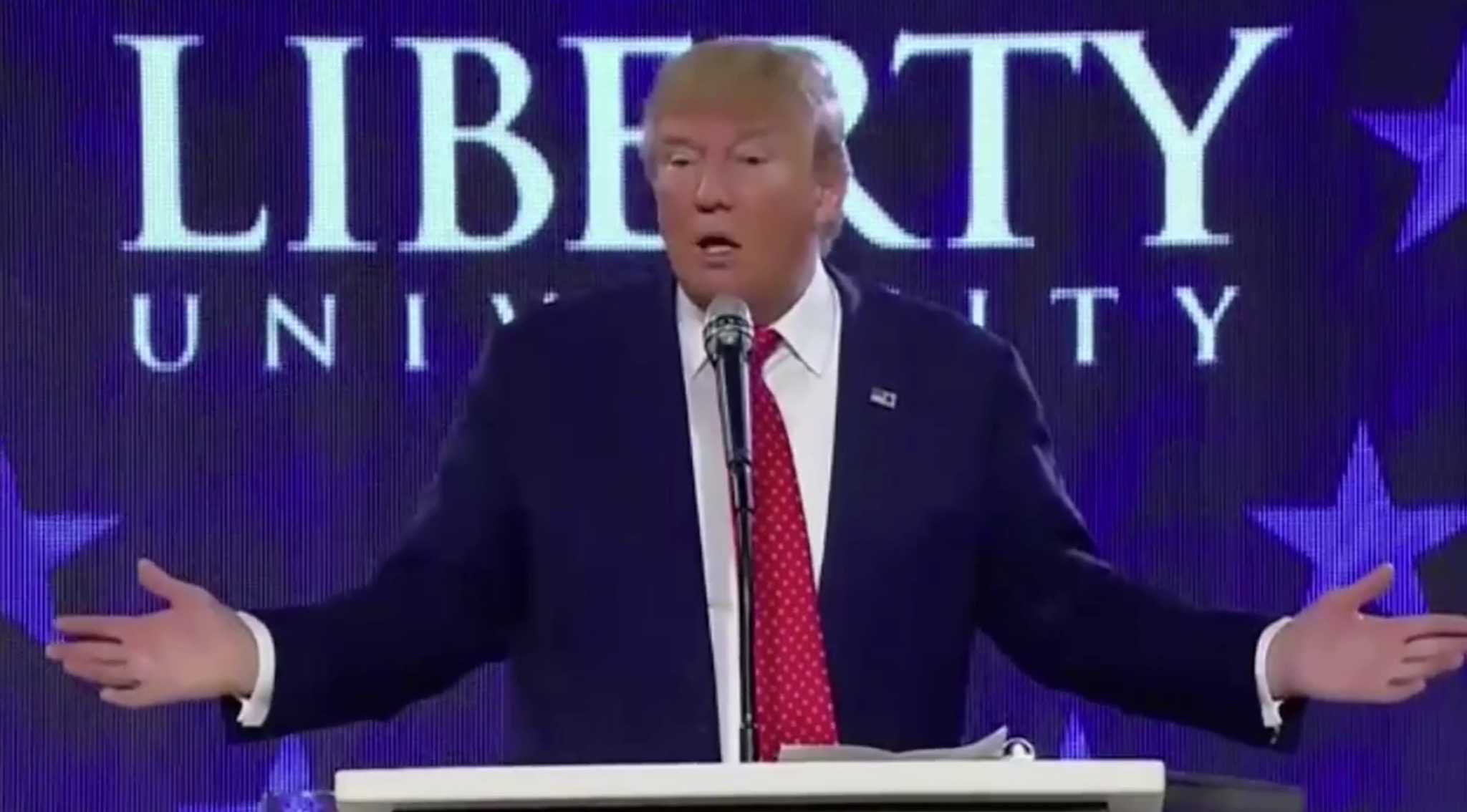

If he really wants the job, presidential hopeful Donald Trump should probably figure out what the office can and can’t do.

Trump showcased his continuing delusion of ultimate executive power to do everything ever at a speech at Liberty University today. And in addition to his lofty goals to construct a huge wall completely sealing off the border between the United States and Mexico (“Someday they’ll call it Trump Wall”) and build a military “so big, so strong, [and] so powerful that nobody is going to mess with us,” he also turned his attention to companies like that have outsourced production overseas to save money on labor and taxes.

“We’re gonna get Apple to start building their damn computers and things in this country instead of in other countries,” Trump said, apropos of nothing.